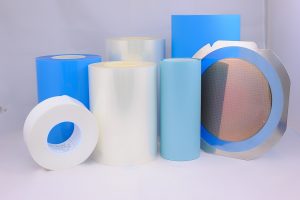

Backside Grinding Tape

◎Universal : BGF–130N, BGF–150N, BGF–180N, BGF-200N。

For wafer thickness 200~600um after grinding process, the advantage is good flatness, small thickness tolerance, small warpage.

◎For Thin Wafer: BGF-105HE, BGF-165HE, BGF-95T-30, FUB-95T-30。

For thin wafer grinding process, a protective tape that can effectively suppress wafer warpage. It has excellent and precise tape thickness and can ensure the thickness of the wafer after grinding process.

◎For Bumped Wafer: FUB-100E-200S, FUB-150E-200S, FUB-95T-100S-30, BGF-95T-100S-30。

For bumped wafer, it provides protection, so that the product is not easy to generate bubbles during the process, resulting in acid seepage and water seepage.

BG Tape (Non-UV Type)

| Item | Backing | Color | Total Thickness (um) | Base Thickness (um) | Adhesive Thickness (um) | Adhesion (N/25mm) | Recommended workpieces |

| BGF-XXXN-AR | PO | Blue | 130/150/180/200 | 100/150 | 30/50 | 0.35/0.85/1.5/2.0 | Standard types ( for wafer Grinding process about 600um~150um of thickness) |

| BGF-105HE-XX | PO | Blue | 130/135/155 | 105 | 25/30/50 | 0.35/0.85/1.5/2.0 | Thin-wafer types ( for wafer Grinding process about 600um~50um of thickness) |

| BGF-165HE-XX | PO | Blue | 185/195/205 | 165 | 20/30/40 | 0.35/0.85/1.5/2.0 | Thin-wafer types ( for wafer Grinding process about 600um~50um of thickness) |

| BGF-95T-30 | PET | Blue | 125 | 95 | 30 | 0.35/0.85/1.5/2.0 | Anti Acid types ( for after wafer Grinding process and with Acid process ) |

| FND-100AE-30 | PO | Blue | 130 | 100 | 30 | 0.35/0.85/1.5/2.0 | Anti Acid types ( for after wafer Grinding process and with Acid process ) |

| FGE-110 | CPP | Blue | 110 | 100 | 10 | 0.35/0.85/1.5/2.0 | Anti Acid types ( for after wafer Grinding process and with Acid process ) |

BG Tape (UV Type)

| Item | Backing | Color | Base Thickness (um) | Adhesive Thickness (um) | Total Thickness (um) | Adhesion (N/25mm) | Adhesion After UV (N/25mm) | Recommended workpieces | Dosage of UV (mj/cm2) |

| FUB-100E-XX | PO | Transparent | 100 | 20/30 | 120/130 | 7.50 | 0.20 | UV types (for after wafer Grinding process, easy to detaping) | 500 |

| FUB-150E-XX | PO | Transparent | 150 | 20/30 | 170/180 | 7.50 | 0.20 | UV types (for after wafer Grinding process, easy to detaping) | 500 |

| FUB-150AE-XX | PO | White | 150 | 20/30 | 170/180 | 7.50 | 0.20 | UV types (for after wafer Grinding process, easy to detaping) | 500 |

| FUB-95T-30 | PET | Transparent | 95 | 30 | 125 | 5.00 | 0.20 | UV types (for after wafer Grinding process, easy to detaping) | 500 |

| FUB-100T-30 | PET | Transparent | 100 | 30 | 130 | 7.50 | 0.20 | UV types (for after wafer Grinding process, easy to detaping) | 500 |

Bumping BG Tape

| Item | Backing | Color | Total Thickness (um) | Base Thickness (um) | Soft Layer Thickness (um) | Adhesive Thickness (um) | Adhesion (N/25mm) | Adhesion After UV (N/25mm) | Recommended workpieces | Dosage of UV (mj/cm2) |

| BGF-105HE-XX | PO-B | Blue | 155/165 | 105 | 50/60 | 1.5/2.0 | NA | For middle-bump wafer | NA | |

| BGF-100AE-XX | PO-B | Blue | 150/170 | 100 | 50/70 | 1.5/2.0 | NA | For middle-bump wafer | NA | |

| BGF-100E-100S-XX | PO-B | Blue | 220/230/250 | 100 | 100 | 20/30/50 | 1.5/2.0 | NA | For High-bump wafer | NA |

| FUB-95T-100S-30 | PET | White | 225 | 95 | 100 | 30 | 12.00 | 0.20 | For High-bump wafer | 1000 |

| FUB-95T-100S-30 | PET | White | 225 | 95 | 100 | 30 | 17.00 | 0.20 | For High-bump wafer | 1000 |